Insight KB gives you permanent visual control of the process in the machine room.

This not only makes it easier to run in the machine, but also makes work much more efficient and safer and minimizes the cost of rejects.

Available in 200, 300 and 400 mm as well as in special sizes and shapes!

As a trained industrial mechanic specialising in precision mechanics, Stephan Ketterer recognised an everyday problem with the metal-cutting process on CNC-machine tools. The view into the machine room is permanently impaired by splashing emulsion during the manufacturing process.

When he told Daniel Braitsch about the matter, they decided to find a solution to this problem together. The aim was to put a product on the market that offers a quick and easy improvement for the CNC-industry.

Thanks to the outstanding network and entrepeneurial knowledge of Daniel Braitsch, together with the technical know-how of Stephan Ketterer, the pair have succeeded in developing – and bringing on the market – a cost-effective, simple solution.

What are the advantages of the V 4.0 clear view disk?

We have developed our Clear view disk to the next level. Thanks to the upgrade to V 4.0 we have reached an even longer service life.

With a completely revised coating on a new substrate, we are able to achieve an even clearer vision into the machine room.

In addition to our own enthusiasm for our products, the enthusiasm of our customers when they first use our products drives us to become even better every day.

We are constantly developing our innovative solution for the CNC industry. With us, you have a competent partner at your side.

We are constantly growing and developing through challenges, experiences, setbacks and successes.

The film can be positioned

freely and flexibly on the machine safety screen. Even curved screens are no problem.

We offer the cost-effective solution for a better view. The beading effect is created by a special coating.

Very low installation effort. No screw mounting necessary. Easy installation thanks to a special adhesive layer. Low installation height of 0.3 mm.

A product made in Germany. What’s more, production can be resumed immediately after assembly.

These are Stephan Kettererand Daniel Braitsch.

As a trained industrial mechanic specializing in precision mechanics, Stephan Ketterer recognized an everyday problem in machining on CNC machine tools. The view into the machine room is permanently impaired by splashing emulsion during the machining process.

When he told Daniel Braitsch about the problem, the two decided to find a solution together. The aim was to place a product on the market that would offer a quick and easy improvement for the CNC industry.

Thanks to the excellent network and entrepreneurial knowledge of Daniel Braitsch and the technical expertise of Stephan Ketterer, they have succeeded in developing a cost-effective and simple solution and bringing it to market.

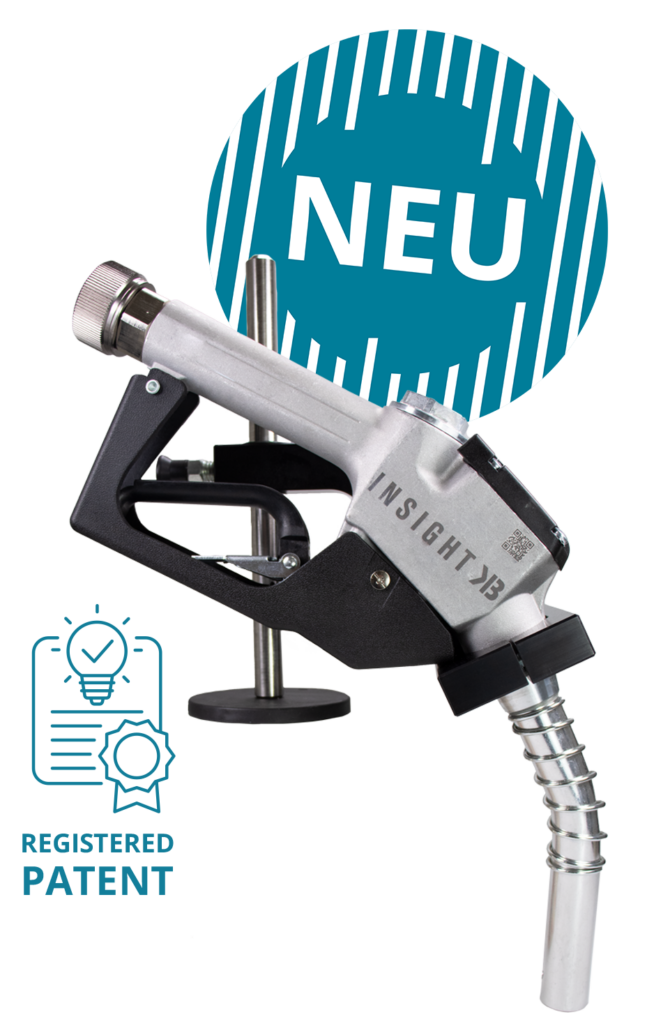

Safe, fast and easy filling – Made in Germany

1x automatic dispensing valve with swivel connection G3/4″ AG to 1″ IG

1x height adjustment incl. magnetic base

The dispensing valve is only suitable for water-miscible cooling lubricants and must not be used for dispensing other liquids.

The flow rate can be regulated using the integrated three-stage release lock. A G3/4″ male to 1″ female swivel joint is installed to prevent the hose from twisting or kinking.

The dispensing valve can be locked in various positions depending on the desired filling height thanks to the integrated height adjustment via a locking pin.

No bolting to the machine necessary. The height-adjustable dispensing valve can be used on any machine thanks to the magnetic base.

The automatic switch-off prevents the tank from overflowing.

120mm travel

360 degree rotatable

In addition to our own enthusiasm for our products, the enthusiasm of our customers when they first use our products drives us to become even better every day.

We are constantly developing our innovative solution for the CNC industry. With us, you have a competent partner at your side.

We are constantly growing and developing through challenges, experiences, setbacks and successes.

Our advantages show why our product is indispensable for your machine rooms.

The film can be positioned

freely and flexibly on the machine safety screen. Even curved screens are no problem.

We offer the cost-effective solution for a better view. The beading effect is created by a special coating.

Very low installation effort. No screw mounting necessary. Easy installation thanks to a special adhesive layer. Low installation height of 0.3 mm.

A product made in Germany. What’s more, production can be resumed immediately after assembly.

Protect your LED machine lights from clouding and impact with our transparent protective screen. We ensure consistent lighting conditions in your machine at all times.

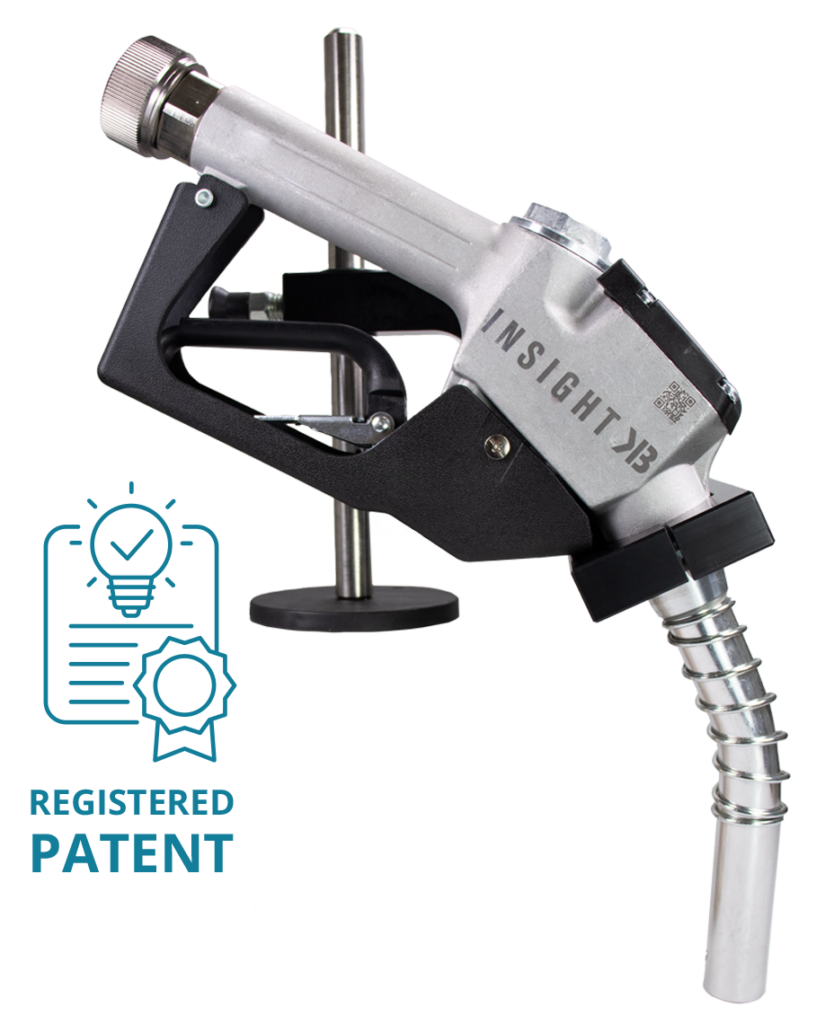

Safe, fast and easy filling – Made in Germany

1x automatic dispensing valve with swivel joint connection G3/4″ AG to 1″ IG

1x height adjustment incl. magnetic base

The dispensing valve is only suitable for water-miscible cooling lubricants and must not be used for dispensing other liquids.

The flow rate can be regulated using the integrated three-stage release lock. A G3/4″ male to 1″ female swivel joint is installed to prevent the hose from twisting or kinking.

The dispensing valve can be locked in various positions depending on the desired filling height thanks to the integrated height adjustment via a locking pin.

No bolting to the machine necessary. The height-adjustable dispensing valve can be used on any machine thanks to the magnetic base.

The automatic switch-off prevents the tank from overflowing.

120mm travel

360 degree rotatable